Our client, SWD, is a leader in metal finishing and fastener sorting and operates a complex 200,000-square-foot facility running 24/7 and processes up to five hundred work orders daily. In this high-volume, metal-heavy environment, parts travel through multiple finishing and sorting stages. With hundreds of metal containers in constant motion, tracking work orders was a daily challenge. Any misplaced order slowed throughput, frustrated workers, and made it harder to respond to customer inquiries.

The Solution: Real Time Location Tracking

SWD chose to go with a WISER Real Time Location Tracking solution. WISER’s system is purpose-built for complex, RF-challenging industrial settings and can track thousands of assets continuously. Furthermore, its software suite is designed with work order and manufacturing processes in mind. It offers easy tag assignment and user-friendly search tools that don’t force staff to complicate their work routines. SWD has transformed their workflow and eliminated costly delays.

The WISER system dramatically improved efficiency at SWD. As Matt Delawder, SWD’s Sales and Marketing Manager/Partner explained, “On any given day we needed the ability to track up to 4,000 parts, with the capability to reassign five hundred work orders to tags each day. This is the best productivity improvement we’ve done in years.”

Key Capabilities That Ensured Success

WISER’s UWB based platform is designed to work in heavy metal environments. And its software was written with non-linear manufacturing processes in mind. There are three capabilities of the WISER solution that really made it ideal for SWD:

- Reliable tracking in metal-heavy, RF-challenging conditions

- Instant tag reassignment which reduces errors and saves hours

- Ability to locate any work order in seconds, not minutes

Let’s go over why each of these are important and how WISER achieves this performance

1. Reliable tracking in metal-heavy, RF-challenging conditions

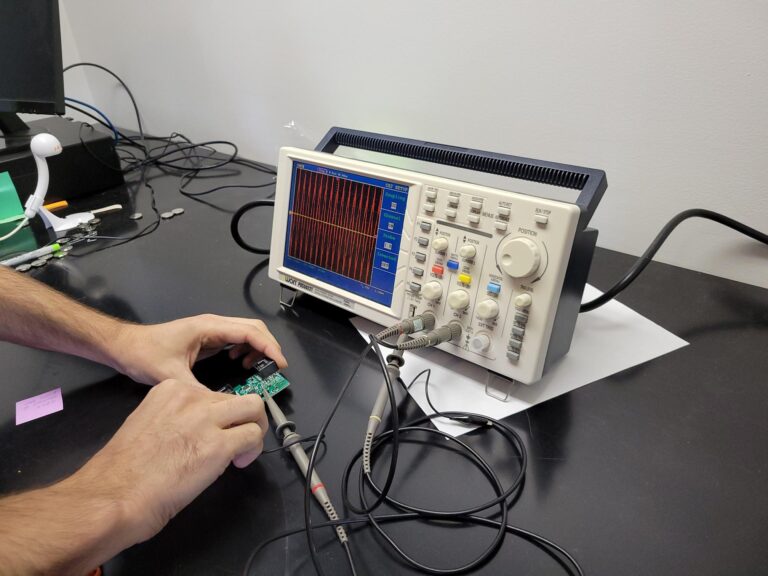

SWD is not an easy setting for RF (Radio Frequency) systems. They do metal finishing on metal parts. Many items like screws and bolts are kept in metal bins that are stacked for processing. There are racks of metal everywhere, and RF signals generally don’t go through metal very well. Here’s a picture showing metal parts at SWD stored in stacked metal containers. Clearly, metal is everywhere.

The WISER system uses Ultra-Wideband (UWB), which measures the time of flight of a signal rather than its signal strength, as BLE and Wi-Fi do. Signal strength methods are easily thrown off by reflections, leading to inaccurate results, especially in metal-rich environments. By timing how long a signal takes to travel, UWB focuses on the most direct path, delivering far greater accuracy even when obstacles are present. For more information on RTLS technologies, visit our RTLS in 2024 guide.

However, with this much metal, most UWB solutions struggle. WISER uses unique algorithms in its calculations that parse out location even more accurately than most other UWB solutions. WISER also uses autocalibration so as obstacles shift or an antenna loses visibility, the system recalibrates and continues to be accurate. So, if a rack of metal boxes is moved from one location to the next, WISER continues to function just fine.

2. Instant tag reassignment which reduces errors and saves hours

The WISER software includes a “Tag Assignment View.” It is a simple-to-use window that lets a user easily scan the WISER barcoded tag and then the work-order, pairing them together in the system. At SWD, this straightforward step was done at receiving, and that was the last scan until shipping. The work-orders could then be tracked real-time throughout the entire manufacturing cycle without any more scans. This saved employees’ time scanning and eliminated errors from missed scans.

You can learn about our easy tag assignment steps in this video:

3. Locates any work order in seconds, not minute

The most frequently used window in the WISER Tracker App is the Map Screen. At SWD, as with most facilities, this shows a bird’s eye floorplan of the facility. At initial view, this screen can show all the tags in the facility although users can choose to show only a subset at a time. To find a single item, the user can search by name, tag number, or other ID in the search bar in the upper left. To find a work order, the user simply types in that work order (tag number and other identifiers could work too) and the screen fades out all the other tags and snaps to the correct location. What could have taken twenty or thirty minutes (or longer if it was really misplaced) now takes only a few seconds.

At SWD, they have mounted screens on the factory floor displaying the WISER Map Screen so employees and visitors can see tags and their movement all the time. These three capabilities helped SWD improve its management of the 3,600 parts per day they track with ease and precision and boost efficiency.

The Results: Greater Visibility and Improved Workflow

By combining metal-tolerant UWB technology, instant tag reassignment, and rapid, real-time location search, WISER’s system has given SWD complete visibility into their 24/7, high-volume operation. Misplaced work orders are no longer a source of delays, customer questions can be answered on the spot, and throughput remains steady even in one of the most RF-challenging environments imaginable. Where other tracking solutions fail or require costly infrastructure, WISER delivers accuracy, flexibility, and speed with minimal disruption. This has transformed SWD’s workflow into a model of efficiency and reliability.

If you are interested in talking with someone from WISER about how we can help at your metal-heavy facility, please feel free to reach out: