Implementing a real-time location system (RTLS) can feel daunting. Many companies worry about steep learning curves or major changes to business processes that could delay the return on investment. At WISER, we’ve built our RTLS solution with simplicity at its core, so accurate location tracking can fit seamlessly into existing processes with minimal disruption.

Traditional RTLS vs. WISER

Conventional RTLS deployments often require extensive training and significant operational changes. Systems that rely on manual scans or checkpoint stations can be particularly challenging to maintain with 100% compliance. That’s why our approach at WISER is different.

Before we install anything, we work directly with OT and IT teams who know the floor best. Our experienced solutions engineers take the time to understand your process flows and flag potential issues early, modifying installation plans as needed and recommending deployment strategies. But before that, the entire WISER system, from hardware to software, is designed to make deployment and usage as easy as possible.

Read more: Technology Comparison

Quick, Flexible Installation

The backbone of the WISER system is our lightweight, omnidirectional antenna. With multiple power options—Power over Ethernet (PoE), solar, or standard wall outlet—it’s flexible enough for almost any environment. And thanks to its design, there’s no need for RF tuning or specialist knowledge. Any technician familiar with cabling and certified to operate a lift can install our antennas in minutes.

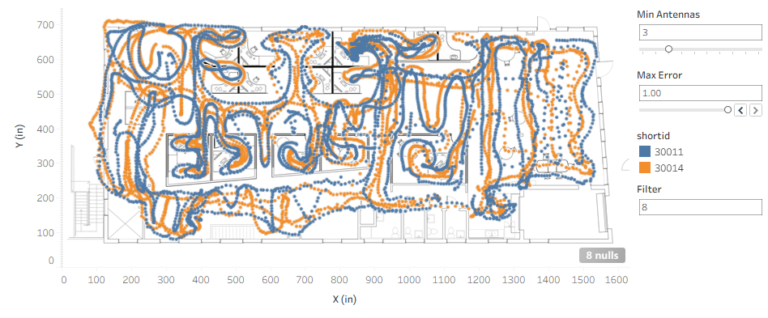

WISER also simplifies installation through its intelligent software. The system auto-calibrates antenna locations, so only a rough estimate of height is needed. Even if an antenna is installed a few feet off-plan, the system adjusts accordingly.

Need to go wireless? No problem. Whether you’re tracking in an office environment or monitoring outdoor zones like a loading dock or factory skirt, WISER’s antennas can run completely wirelessly using solar or AC power—no trenching or long cable runs required.

Minimal Upkeep, Maximum Adaptability

As your operations evolve, WISER evolves with them. If machines are moved or layouts change, our system recalibrates automatically without any need for re-tuning, or system downtime. The omnidirectional antennas and auto-calibration allow the system to adjust to new reflection patterns even in metal-heavy environments, maintaining location accuracy without intervention.

In contrast, many alternative RTLS systems require full re-tuning of antennas, additional antennas around a new piece of large equipment like a crane or CNC machine, and likely recalibration. Just a minor shift in large equipment or racking can mean sending a crew up in a lift to re-tune. WISER also builds in redundancy, so even if an antenna is blocked or loses power, the system maintains full accuracy with the remaining antenna coverage.

For major layout changes, such as adding or moving a station or even a production line, the WISER antenna infrastructure will continue to operate just as before. All that’s needed is updating the floorplan into the WISER system. Upload your new floorplan, map antenna locations, and you’re ready to go. Users familiar with the system can do this without any support from WISER, but WISER technicians are always available to help.

Scaling with Ease

WISER is designed to grow with you. Importantly as the data from WISER informs you of potential bottlenecks and points of inefficiency, you can add a production line, move a station, or take other actions without affecting the WISER RTLS system. Expansion doesn’t require overhauling your setup or retraining your team. Adding new coverage areas to an additional building or even outside the skirt of your factory is straightforward too. Just install additional antennas, upload the floorplan, and do a simple calibration of just that area.

Effortless Day-to-Day Use

As mentioned at the beginning, WISER’s solutions engineers are very familiar with using WISER in a manufacturing setting and work with our clients on how best to deploy WISER with minimal behavioral changes. For example, when tracking work orders or subassemblies, we often advise clients to simply tag items at the start, often linking the tags to the paperwork, and remove tags at the end of their process.

Once associates link tags to work orders at the beginning of a workflow, the system continuously and automatically tracks items in real-time, updating location information without further manual intervention. At the end those tags are removed from the work order, put in a bucket for future reassignment, and the cycle continues.

Unlike traditional barcode systems, with WISER there’s no repeated scanning required at each step, eliminating errors and missed scans. Instead, a single intuitive application can handle tagging and locating items. And for clients interested in integrating location data via API that can be done as well.

Immediate ROI and Further Efficiencies with WISER

Immediately after installation, teams benefit from clear, actionable location data, significantly reducing time spent searching for items. With precise tracking available from day one, production managers can confidently monitor workflow and ensure correct staging and processing of materials.

While immediate efficiency improvements are clear, WISER’s value grows exponentially over time. With detailed historical data on material movements and workflow, organizations can analyze and optimize processes for even greater productivity gains and cost savings.

Conclusion

RTLS doesn’t have to be complicated. WISER has reimagined location tracking to be simple, flexible, and powerful so your team can focus on what matters most: results.