In today’s competitive industrial environment, process improvement is more than a buzzword—it’s a mandate. Manufacturers are under pressure to deliver more output with fewer resources while still providing higher quality and shorter lead times. It can seem impossible. However, by leveraging process improvement strategies paired with digital transformation, manufacturers can meet customer requirements and land on top. But to get the most out of these tools, accurate high-quality data is critical. RTLS systems like WISER’s can be a game changer in performance.

In this post, we explore how RTLS technology—especially UWB-based platforms like WISER—can unlock powerful process improvements and serve as a foundation for meaningful digital transformation.

What Is Process Improvement in Manufacturing?

Process improvement in manufacturing is the structured effort to make production workflows faster, more efficient, and more reliable. It’s all about doing more with less—reducing waste, increasing output, improving quality, and lowering costs.

At its core, process improvement means finding smarter ways to work. It could involve eliminating unnecessary steps, automating manual tasks, or even redesigning a layout to shorten travel time between stations.

The goal is to optimize every step of your production process to deliver better results with fewer resources.

Why Process Improvement Is Essential for Digital Transformation?

Digital transformation in manufacturing refers to the adoption of advanced digital technologies, such as, ERP, MES, IoT, and AI, to connect, monitor, and optimize production systems. The ultimate goal is to create a smarter, more agile, data-driven factory. With better and continuous information, the factory should be able to improve reactions to issues, anticipate problems, and be prepared to pivot in the future. To stay competitive, using these digital tools is becoming increasingly important for manufacturers to be successful.

But here’s the catch:

Digital transformation doesn’t fix broken processes—it digitizes them.

A manufacturer must do the hard work of process improvement to fully understand their workflows and processes first. Without optimized, well-documented, and repeatable workflows, digital tools often amplify inefficiencies instead of solving them. That’s why process improvement is a critical prerequisite. Streamlined processes and a strategy to continue streamlining will ensure higher returns from your technology investments.

Where does a digital twin fit in digital transformation?

A digital twin bridges the gap between process improvement and digital transformation by providing a real-time, virtual replica of manufacturing operations. As a process improvement tool, it enables manufacturers to visualize inefficiencies, monitor workflows, and test changes before implementing them on the floor. As a core component of digital transformation, the digital twin integrates real-time data from systems like ERP/MES, business intelligence platforms, and IoT to create a connected, intelligent environment. This not only improves operational visibility and decision-making but also empowers teams to be more agile, predictive, and aligned.

Importantly, the digital twin turns raw operational data into value by linking it to processes, timelines, and decision points. It allows manufacturers to simulate scenarios, monitor performance in real time, and continuously refine their operations. As McKinsey & Company noted with digital twins, “companies have reduced transportation costs and labor by as much as 10 percent, while increasing consumer promise—meaning allowing organizations to more reliably deliver on their promises to customers—by up to 20 percent.“

In short, the digital twin is both the engine and the roadmap for smarter, more efficient manufacturing.

By improving processes first, manufacturers create a solid foundation for scalable, sustainable transformation which will unlock the full value of their digital ecosystem. And the second piece is ensuring that accurate data is being fed into the digital system. If only estimates are used, those estimates will rarely be corrected and improved. The advice from the digital system will be based on past assumptions rather than real world changes happening on the factory floor.

RTLS: A Critical Enabler of Digital Transformation

The missing piece in this scenario is accurate, continuous real-time data about workflows. As manufacturers digitize, this real-time visibility becomes increasingly non-negotiable. Traditional tracking methods like barcodes and RFID gates only provide snapshots in time. RTLS fills the gap by providing continuous, high-resolution location data. It’s the difference between basing a decision on 5 photos of a process versus a continuous video. You’ll make a better decision if you can view the whole video.

RTLS plays a critical role in digital transformation by powering digital twins with live spatial data, enabling automated workflows such as alerts and routing, supporting lean operations through real-time flow tracking, enhancing AI-driven analytics, and improving traceability and compliance across the production floor.

In short, RTLS transforms the physical world into actionable digital intelligence—making it essential for any smart factory or Industry 4.0 initiative.

Aligning RTLS with Process Improvement Goals

RTLS is a game changer in terms of providing real time data to any process improvement or digital transformation effort. With an RTLS system like WISER’s, any piece of equipment, workorder, tooling or other item can be entered into the system with a single scan and then its location is constantly monitored as it travels through processes. This enhances decision-making by feeding reliable location data into systems like ERP, MES, and business intelligence platforms and speeds up meeting process improvement goals.

From Discrete Scans to Continuous Visibility

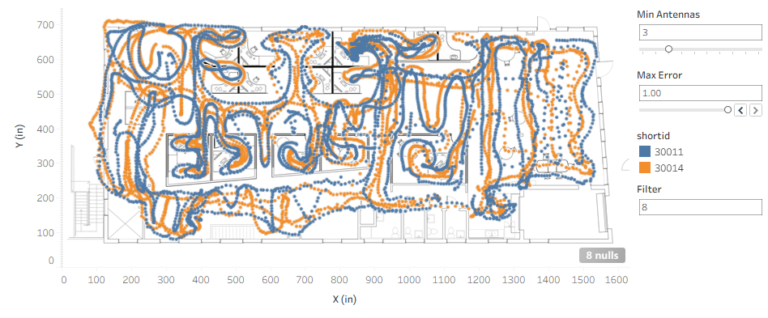

Traditional systems give you discrete data. They capture only a few points in a workflow or snap a few pictures. RTLS offers a continuous live feed of movement, delays, and process interactions or the full video. A system like WISER’s offers basic logic by using zones. The factory can define zones for work areas, hold areas, no entry areas, etc. If a tagged item or work order enters or exits a zone it can be recorded for analysis or even trigger an alert to take action. An example alert would be notifying a team when a part enters a rework zone. The historical data can also be leveraged to create data-rich spaghetti diagrams or heat maps for analyzing material or work order movement.

And for ongoing efficiency improvement, RTLS makes time-and-motion studies effortless and ongoing. Manufacturers can test whether process improvement initiatives are working and adjust if needed.

How to Best Adopt RTLS for Your Own Facility?

Most companies start by using RTLS to locate missing assets, tools, or carts. This often covers the cost of installation and gives a strong ROI right away. However, the real return on investment comes from using location data to understand and improve the flow of work itself. It is an extremely valuable tool that is easy to fit into any process improvement initiative.

Typically, companies begin with a focused use case to solve a visibility pain point. An RTLS system like WISER’s which is easy to expand over time and can handle multiple use cases concurrently is ideal to grow with company needs. As trust in the data grows, many clients expand usage to automate process steps and eliminate manual input. Over time, RTLS becomes a core source of operational intelligence that feeds real-time data into process maps, digital twins, and optimization tools.

Ultimately, RTLS evolves from a search tool to a strategic enabler of continuous improvement.

Final Thoughts

RTLS is an excellent locating tool, but it offers so much more value. In truth, it’s a critical enabler of lean manufacturing and digital transformation. When used intentionally, it helps manufacturers increase throughput, eliminate waste, and improve quality, Its accurate data can become the key driver for digital twins to create useful models and simulations that reflect the real world. It also powers predictive analytics and smart automation, giving manufacturers the visibility and agility they need to stay competitive.

Whether you’re tracking WIP, managing rework, or preparing for Industry 4.0, RTLS gives you the real-time data you need to transform how work gets done.

Learn more about how WISER RTLS can improve your processes and

support your digital journey: