1. Tariff Pressures Demand Smarter Operations

Manufacturing is a dynamic industry that must constantly respond to changes in demand, economics, and policy—and today is no exception. In a time of shifting tariffs and global supplier realignments, having a tool that gives manufacturers clear insight into where to improve efficiency is more valuable than ever. Today, rising duties are reshaping supply chains and squeezing margins, whether components travel thousands of miles or just across town. Manufacturers that reshore production absorb higher domestic labor costs, while those that stay offshore pay tariffs on every incoming part. In either scenario, the levers for protecting profit are the same: cut waste, stretch assets, and unlock data-driven agility.

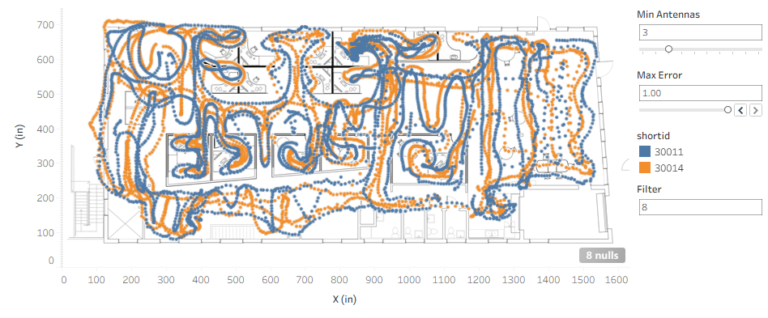

WISER Systems’ ultra-wideband real-time locating system (RTLS) equips plants with that agility from the ground up. Sub-meter tracking of tools, work-in-process, finished goods, and mobile equipment exposes hidden inventory cushions, idle machine capacity, and routing bottlenecks the moment they appear. Purchasing teams feed live counts into their Material Requirements Planning (MRP) systems to consolidate shipments and dodge peak duty windows; production engineers analyze dwell-time heat maps to balance line speeds before ordering extra robots or presses; and operations leaders reconfigure floor plans in minutes by uploading a revised layout, avoiding the costly recalibration that plagues legacy tracking systems. In short, WISER turns tariffs from a fixed cost into a variable one—something you can manage, mitigate, and often avoid altogether through smarter decisions backed by real-time data.

2. Leaner Inventory, Lower Duties

One of the quickest tariff wins arrives through inventory compression. By pinpointing tools, work-in-process, and finished goods with sub-meter precision, WISER eliminates the hours employees spend hunting for misplaced items and the buffer stock companies hold “just in case.” Every dollar trimmed from on-hand inventory is a dollar no longer subject to duty. At a twenty-five-percent tariff rate, cutting safety stock by $500k frees $125k in cash each year. That narrower footprint also cuts carrying costs—less warehouse space, lower insurance premiums, and fewer write-offs for obsolete parts. In short, real-time visibility turns what would have been material and tariff expense directly into working capital.

3. Tariff-Smart Replenishment and Capital Avoidance

Real-time counts from WISER flow into purchasing systems, allowing buyers to time inbound orders more intelligently. Instead of rushing small shipments at peak duty rates, they can consolidate loads once data shows genuine demand, often pairing the new volume with price breaks that offset remaining duties. The same location intelligence shines a light on hidden capacity inside the plant. By tracking how long each machine sits idle, how often changeovers occur, and where work-in-process queues form, WISER helps production teams squeeze more throughput from the assets they already own. That higher utilization frequently removes the need to import additional capital equipment, sidestepping both the purchase cost and any tariffs that would attach to the new machinery itself.

Plants might, for example, uncover enough spare robot time to avoid buying another weld cell, discover that feeder setup rather than machine speed is the real bottleneck in their pick-and-place machine, or reveal gaps in mold-press schedules that postpone importing a new injection-molding machine.

4. Rapid Reconfiguration Without Recalibration

In periods of economic uncertainty, manufacturers may have to pivot quickly to new suppliers or product mixes, and the last thing they need is a disruptive overhaul of their location-tracking system. Traditional solutions typically require costly site surveys and hours of downtime whenever a line moves. WISER eliminates that burden: its ultra-wideband anchors maintain sub-meter accuracy in metal-rich environments even without line of sight, so a layout change is as simple as uploading an updated floor plan to the WISER console. The mesh continues to operate without manual intervention—no physical recalibration, no outside technicians, and no production stoppage. Once the new configuration is live, managers can query historical and real-time data in SQL or stream it straight into their ERP or MES via API, instantly validating cycle-time gains, material flow, and routing improvements.

Conclusion

Tariffs may be unpredictable, but the strategies to protect margins are not. By combining sub-meter visibility with rapid reconfigurability, WISER RTLS lets manufacturers trim duty-laden inventory, unlock idle capacity, and pivot processes without costly recalibration. The result is a leaner, more resilient plant that turns tariff risk into competitive advantage—keeping cash on the floor instead of in customs. Even better, the same location data that eases today’s tariff squeeze also feeds tomorrow’s automation, sustainability reporting, and predictive-maintenance programs. In short, an investment in real-time location keeps paying dividends long after the tariff headlines fade.