Real-Time Location Technology at FABTECH 2025: Key Takeaways and the Future of Smarter Manufacturing

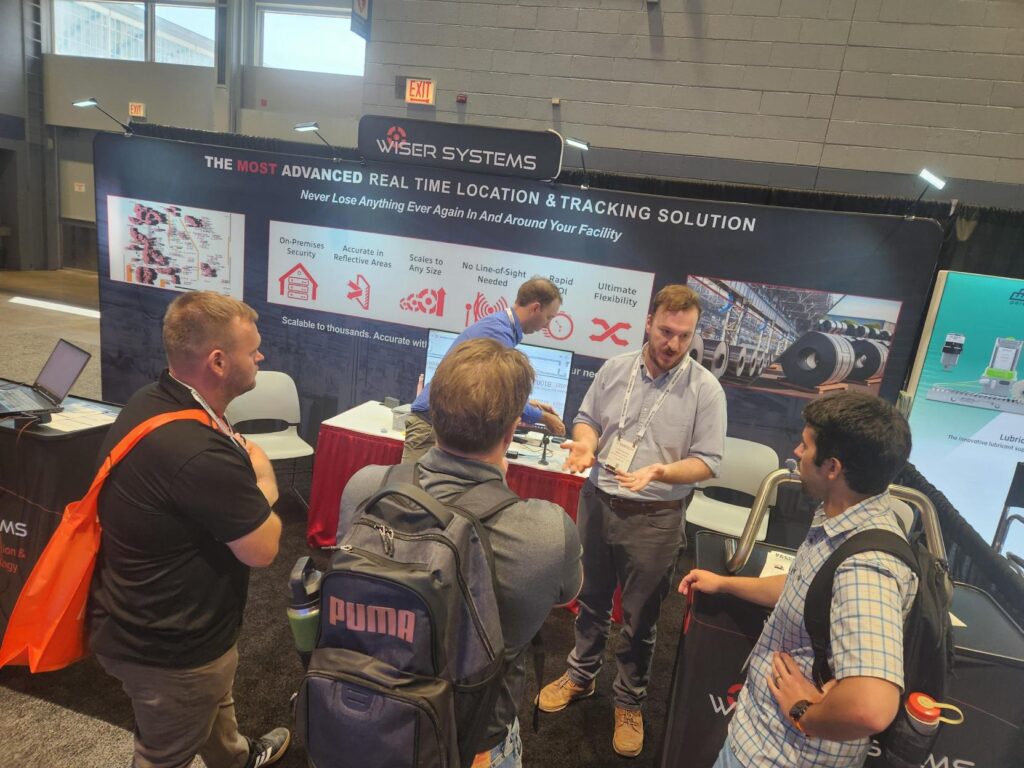

FABTECH 2025 wrapped up in Chicago last week, and what an incredible show it was for the WISER team. Over the course of the event, we connected with manufacturers from all over the world, answered questions, and demonstrated how our real-time location technology (RTLS) is transforming operations for facilities of all sizes. From live demos to deep discussions about data and analytics, here are the highlights and why RTLS is becoming a must-have tool for small and medium-sized manufacturers as well as large multi-nationals.

Why Manufacturers Are Taking Notice

At FABTECH, one theme came up again and again: visibility is power.

Small and medium-sized manufacturers face challenges that RTLS can address immediately, including:

- Losing tools, fixtures, gauges, or metal parts across busy shop floors

- Tracking work-in-progress (WIP) through custom production steps and testing areas

- Finding cost-effective tracking solutions for 30,000–50,000 sq. ft. facilities as well as those larger than a quarter million sq. ft.

Attendees were surprised to learn that the same accurate, scalable tracking technology used by large enterprises is accessible and affordable even for smaller facilities. WISER’s flexible cost structure, whether CapEx or OpEx, means manufacturers can start improving visibility without massive upfront investment. In addition, the antennas are generally placed 75 feet apart indoors and 150 feet outdoors so a large area can be covered with only a few antennas. That lowers both installation and maintenance costs.

Visitors also appreciated how the WISER system easily scales in terms of both assets tracked and use cases. Clients can start tracking a few dozen key assets and over time grow to tracking 10s of thousands of items using the same equipment. For example, if a company wants to start with just tracking a few dozen carts, they can later use the exact same system to track thousands of work orders once the WISER solution is installed.

From Finding to Analyzing: Turning Location into Insight

Our live demos showcased the evolution of WISER from a simple “find it fast” tool to a data powerhouse that has accuracy as its centerpiece. As CEO Dr. Seth Hollar and Director of Engineering Andy Kerfonta explained, WISER’s system does more than just track. It empowers manufacturers with actionable analytics.

Phase I – Search & Find

Out of the box, WISER enables instant location of parts, tools, and equipment, reducing wasted search time and preventing unnecessary replacement costs. Most clients see a positive ROI within a year based on this use case alone.

The initial ROI comes from saving employee time searching for misplaced work orders, tooling, or other equipment. Reducing search times from dozens of minutes to seconds can be transformative for a site’s efficiency. In cases where the items are never found, such as dies for metal stamping, those might have to be remade or rebought creating an additional expense. As another example, one of our clients is an aerospace manufacturer who must ensure made parts have been tested with appropriately calibrated gauges. Before WISER, this facility was having trouble finding appropriately calibrated gauges and lost time searching for them or unnecessarily sending gauges in for re-calibration due to uncertainty. These are all significant savings that affect the bottom lines of our customers’ sites.

Phase II – Track and Trace with Charts and Analytics

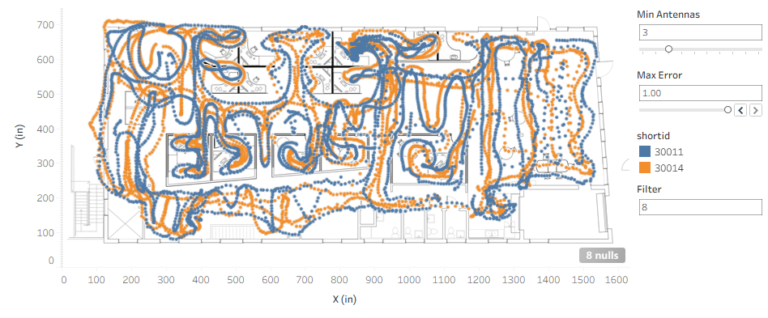

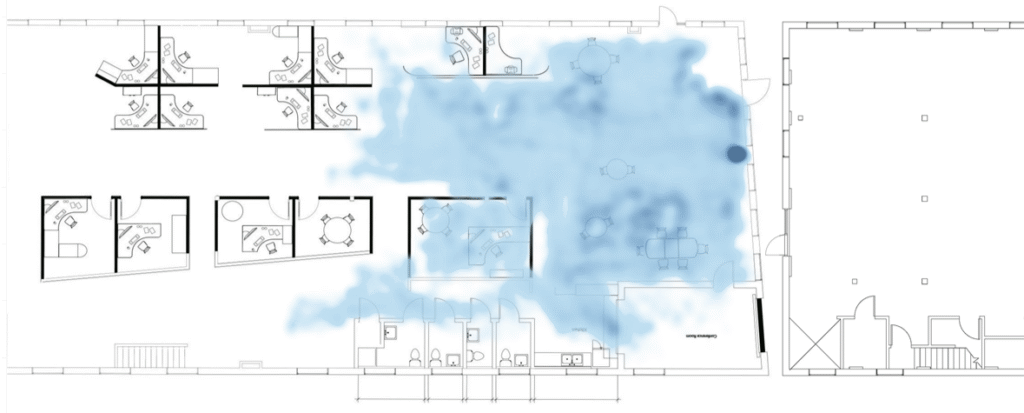

Because customers own their data, they can store and analyze their historical data to uncover hidden inefficiencies. Tools like Power BI, Tableau, or Python can turn raw location data into heat maps, spaghetti diagrams, and waterfall charts that reveal bottlenecks and workflow delays. Many clients are already using heat maps and spaghetti diagrams but the data behind these analyses is based on a few days of data collection and extrapolations. With real time and accurate data like WISER’s, these analytical tools have new power, and managers can continually test whether their process improvements are working.

Read more: Easily Create Heat Maps in Tableau Using WISER Data

WISER is also designed to easily integrate its location data into a client’s ERP and/or MES system with its straightforward REST API. This enables clients to seamlessly pair their internal information about the items being tracked and even their planned routes along with the WISER location data.

Phase III – Predictive Analytics & AI

With rich historical and real-time data, WISER supports custom dashboards, predictive analytics, and even AI-driven insights to detect buildups and anticipate slowdowns before they impact production. Companies, both large and small, are making major investments today in improved analytics and AI toolboxes. However, those investments only work with a strong understanding of the process improvement strategy and high-quality data. WISER provides high-accuracy, 24/7 data and has the in-house knowledge of process improvement to help those tools return the greatest rewards.

This phased approach means companies can start small by just finding items and over time naturally evolve toward full Industry 4.0 capabilities.

Quality, Accountability, and the Road to Industry 4.0

Finally, RTLS doesn’t just save time; it raises the bar for quality assurance and accountability. By knowing where every tool, fixture, and piece of WIP is in real time, manufacturers can avoid costly mistakes such as using uncalibrated equipment or missing critical audit trails. Historical data also creates a valuable framework for continuous improvement, giving managers visibility into how long items stay at each production step and where processes can be tightened. This can provide peace of mind to manufacturers and their clients. These tools also make audits a straightforward part of the manufacturing process rather than a major headache.

The result of all this? With greater visibility you get faster throughput, lower costs, and improved quality which are all critical steps toward the automation, efficiency, and savings that define Industry 4.0.

FABTECH 2025 may be over, but the momentum is just beginning. WISER’s RTLS technology provides more than location tracking; it lays the foundation for smarter factories where data drives decisions and efficiency is built into every process.

Ready to Learn More?

If you missed us at FABTECH 2025, don’t worry. You don’t have to wait until FABTECH 2026 to start the conversation. Whether you’re looking to eliminate lost tools, gain process insights, or prepare your facility for the next wave of manufacturing innovation, now is the time to explore how RTLS can transform your operations.

If you are interested in talking with someone from WISER about how we can help at your facility, please feel free to reach out. You can contact us via our website, email, or phone.