Manufacturing Work-in-Process Tracking

Transform your production line with real-time work-in-process tracking. WISER’s automated system provides continuous visibility, eliminating manual errors and delays. By using wireless tags, you gain instant insights into every part and work order, ensuring smooth, efficient operations. Embrace clarity and control with our cutting-edge WIP tracking solution.

Real-Time Work-in-Process Tracking for Manufacturing Visibility

Real-time work-in-process tracking gives manufacturers continuous, automatic visibility into parts, batches, kits, and work orders as they move through production. Instead of relying on periodic barcode scans, paper travellers, or delayed system updates, we provide a live digital map of all WIP on the floor so teams always know where work is, what stage it is in, and whether it is moving as expected. This level of visibility is essential in modern manufacturing environments where workflows are complex, non-linear, and highly time sensitive.

With our automated WIP tracking system, manufacturers eliminate the uncertainty that leads to lost work orders, idle stations, and constant searching. By attaching wireless tags to WIP containers or work orders, location data is captured continuously and displayed in a centralized dashboard without manual effort. This allows operations, quality, and production teams to see issues as they develop, keep work flowing through every step, and maintain control over manufacturing process tracking from start to finish.

The Challenge of Managing Work-in-Progress Without Real-Time Visibility

When work-in-progress is tracked using spreadsheets, paper travelers, or manual barcode scans, visibility is always delayed and incomplete. In busy manufacturing environments, parts and work orders are constantly being moved between stations, staging areas, testing, rework, and quality holds. Without real-time WIP tracking, it becomes easy for a container to be set aside in the wrong area, a job to stall unnoticed, or a critical batch to go missing entirely.

These gaps in visibility create real operational consequences. Production teams spend valuable time searching for jobs instead of working on them. Supervisors discover bottlenecks only after downstream stations are already waiting. In non-linear workflows, items can skip required steps or fail to return from rework on time. Over time, these issues increase cycle times, reduce throughput, and put on-time delivery and compliance at risk. This is why manufacturers are moving away from manual WIP tracking methods toward automated, real-time manufacturing WIP tracking systems that provide continuous insight into where every job is and what needs attention next.

How WISER Delivers Automated Real-Time WIP Tracking

We enable real-time WIP tracking by automatically capturing the location of work-in-process items as they move through production. Instead of relying on manual scans or operator input, our system creates continuous visibility using wireless location technology purpose-built for manufacturing environments.

Continuous Location Tracking Without Manual Scans

Live Digital Map of Manufacturing Work-in-Process

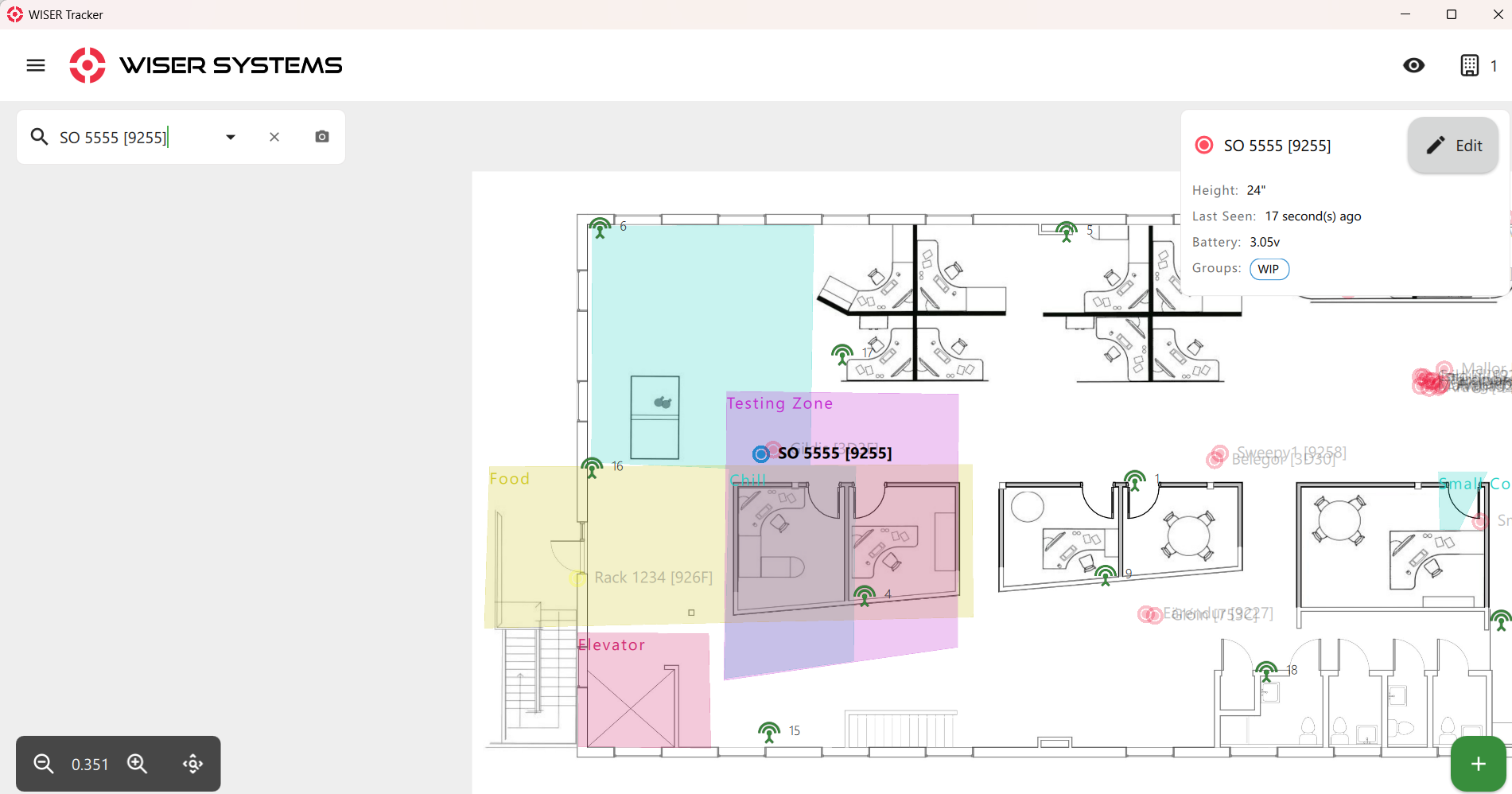

All location data is displayed in a centralized dashboard that shows a live digital map of the shop floor. Operations and production teams can instantly see where each job is, what stage it is in, and how long it has been there, supporting accurate manufacturing process tracking across linear and non-linear workflows. WISER also offers advanced data visualization and analytics services to help process data and pull valuable insights.

Built-In Control for Complex and Regulated Processes

Our platform supports geofences, dwell-time monitoring, and process rules that help ensure work follows the correct path. If a job sits too long, skips a required step, or leaves a controlled area early, teams are alerted in real time. This prevents idle or lost work orders while strengthening traceability and compliance.

Operational Impact of Real-Time Manufacturing WIP Tracking

Real-time WIP tracking gives manufacturing teams immediate control over how work moves through the plant. With continuous visibility into the location and status of every work order, parts, and kits, teams eliminate time spent searching for missing jobs and avoid delays caused by misplaced or idle WIP.

Supervisors can see where work is accumulating, which steps are taking longer than expected, and which stations are at risk of running out of work.

This allows issues to be addressed as they occur instead of reacting after schedules have already slipped. Over time, this level of insight shortens cycle times, improves throughput, increases on-time delivery performance, and creates a more predictable production flow driven by accurate, automated manufacturing WIP tracking.

Where Real-Time WIP Tracking Delivers the Most Value

Real-time WIP tracking delivers the greatest impact in manufacturing environments with high mix, high value, or complex workflows where work does not move in a simple linear sequence.

This includes operations with frequent testing and rework loops, shared resources, quality holds, or strict traceability requirements. Production and operations managers rely on this visibility to keep work flowing, while quality and compliance teams depend on it to maintain accurate records of where each item has been and how long it has spent at each step.

Manufacturing engineers and continuous improvement leaders use the data to identify bottlenecks, reduce wasted motion, and support data-driven process improvements. In these environments, automated WIP tracking becomes a foundational system that supports daily execution, long-term optimization, and consistent delivery performance.

Request a Real-Time WIP Tracking Demo

Frequently Asked Questions

What is real-time WIP tracking in manufacturing?

Real-time WIP tracking is the continuous, automatic visibility of work-in-process items such as parts, batches, kits, and work orders as they move through production. Using wireless tags and a centralized dashboard, we create a live digital map that shows where each job is and how it is progressing without relying on manual scans or paperwork.

How does automated WIP tracking differ from barcode or RFID systems?

Automated WIP tracking captures location and movement continuously rather than only when someone scans an item. Barcode and basic RFID systems provide snapshots that depend on operator compliance, which often leads to gaps in visibility. Our system reports WIP location in real time, ensuring work orders never disappear between steps.

Can real-time WIP tracking support non-linear workflows and rework loops?

Yes. Many manufacturing processes do not follow a strict sequence and include testing, rework, or staging loops. Real-time WIP tracking follows each item’s actual path through the facility and can alert teams if work skips a required step or sits too long in a specific area.