A key point in any purchasing decision is always going to be what is the ROI. In other words: Are we going to get our money’s worth? At a broad level, a reliable Real-Time Location System (RTLS) that fits your use case is going to broadly give you time saved, assets found faster, and improved visibility. But you get real clarity when you start examining ROI through the lens of a specific use case and start building a quantifiable case.

In this example, we’ll step inside a large electronics manufacturing facility—roughly 150,000 to 250,000 square feet—that produces complex antennas. Each product must move through multiple workstations, from assembly to testing, calibration, and sometimes rework. There’s no conveyor system here, but instead a highly manual, cellular process where parts and equipment are constantly in motion.

The Hidden Cost of Searching for Tools

Among the many moving parts in this facility, one category stood out: specialized testing equipment. Each device is finely calibrated to ensure the antennas being built project the correct radiation pattern. Because testing equipment moves from station to station, it often gets shuffled, misplaced, or forgotten in a different area of the facility.

When that happens, production slows or even stops while technicians hunt down the missing unit. This is more than a minor inconvenience because it’s a direct hit to labor productivity and throughput.

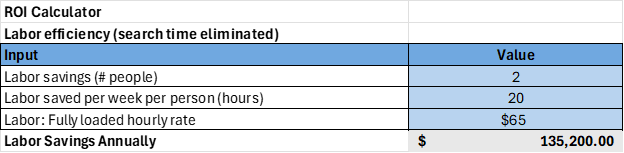

In this particular facility, two employees spent about 20 hours each week managing and locating testing equipment. With a fully loaded labor rate of $65/hour, that’s roughly $135,000 per year dedicated purely to tracking down equipment.

With WISER’s RTLS solution, that same search time drops from hours to the few minutes it takes to walk over to a shelf. These were trained qualified individuals as well. So that’s labor that can now be spent building, testing, and shipping, instead of searching.

This is a pretty easy calculation and WISER has made a template to walk you through the steps. Below we lay out we calculated labor savings for this scenario:

Machine Downtime: The Silent ROI Killer

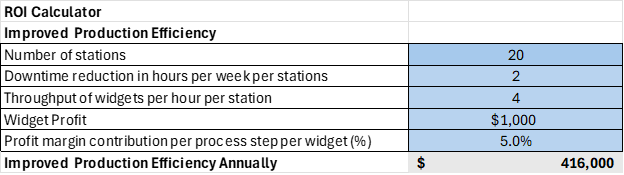

But labor isn’t the only source of ROI. Downtime is the invisible cost that quietly eats into production margins.

When a workstation can’t operate because a piece of test equipment is missing, the impact cascades. Operators wait. Production queues build up. And because this type of manufacturing process isn’t smooth or linear, downtime doesn’t appear as one big block on a chart. It is scattered across the facility and can impact multiple jobs. In addition, the time adds up with a few minutes here, a half-hour there, and occasionally an entire shift lost when a tool truly disappears.

This facility has about 20 stations using this testing equipment. Across 20 test stations, even two hours of downtime per station per week quickly adds up. Multiply that by the throughput of say, a new widget every 15 minutes, and the production loss becomes significant.

If each product contributes about $1,000 in profit, the difference between running at full capacity and waiting for missing tools quickly becomes a measurable dollar figure.

Below is our estimate of those savings:

Calculating the ROI

What’s powerful about this use case is how quantifiable the ROI becomes. By combining labor savings, reduced downtime, and increased throughput, this facility saw a positive ROI within just a few months.

And that doesn’t even include the “soft savings” like better use of calibration schedules, reduced stress on staff, or improved delivery timelines. For some manufacturers, avoiding late-shipment penalties can be another major source of ROI that’s easy to overlook until it hits the balance sheet.

A Broader Lesson: Start with the Right Assets

This story illustrates a broader lesson about implementing RTLS: start with the assets that matter most to your process.

For this electronics manufacturer, that meant tracking testing equipment first, which wasn’t the most expensive item but was causing the biggest bottleneck. WISER was able to spend time with the team to identify this opportunity for improvement and develop a strategy to use RTLS to solve that problem. Once the facility saw measurable improvements there, it became clear how to extend the system to other areas.

RTLS isn’t just about knowing where something is. It’s about how understanding how that knowledge will improve your operation. In this case, it was worth hundreds of hours, faster throughput, and smoother operations.

Turning Insight into Action

At WISER, we often work with manufacturers to help calculate ROI for their unique operations. Every process is different, but the method is the same: identify the friction points, measure the impact, and quantify the return.

We can also provide a custom ROI calculator template that helps companies plug in their own labor rates, downtime estimates, and throughput data to see exactly when and how the investment pays off.

Because when you can see your return, real time track is about more than tracking assets—it’s about transforming your operations.

We can help you identify where your facility’s hidden ROI lies and how quickly you can start realizing it. Contact us with your questions, we’d be happy to discuss it and hopefully help out. You can contact us via our website, email, or phone.