Electronic Subassembly

Asset Locating System for Electronics Manufacturing

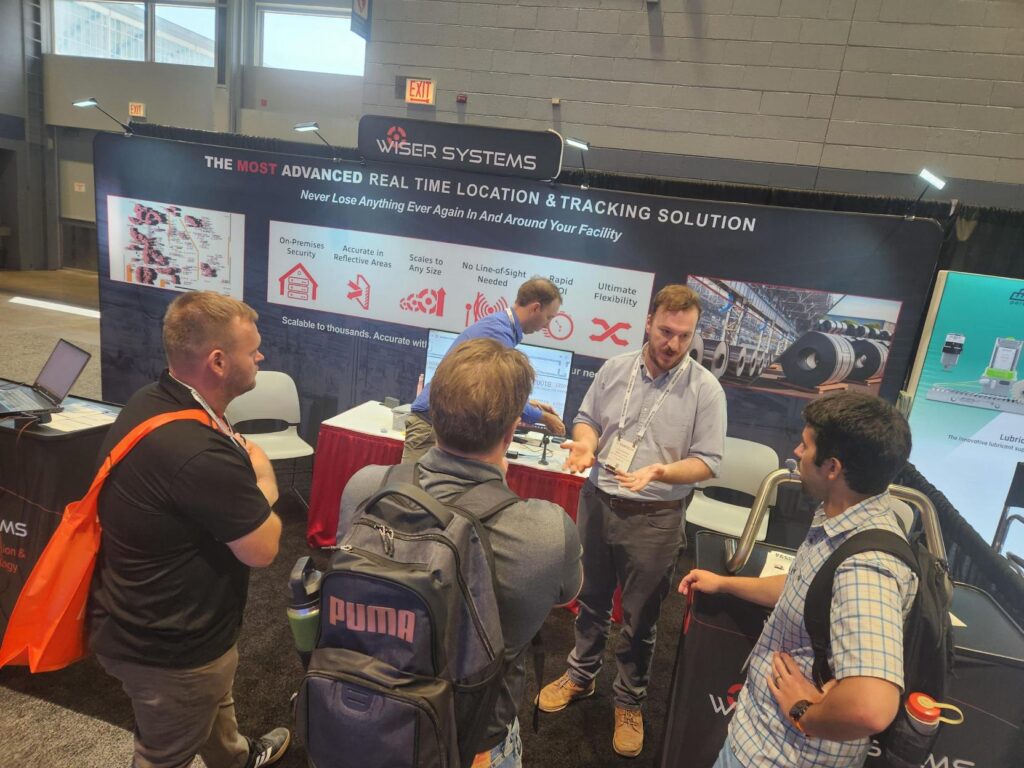

Modern electronics manufacturing demands instant visibility. WISER’s asset locating system for electronics manufacturing delivers real-time tracking of WIP, tools, PCBAs, semiconductors, and subassemblies with sub-meter accuracy. The system uses ultra-wideband technology and auto calibrating wireless mesh network to locate every tagged asset across your facility. With us, operators stop searching, and production keeps moving.

Precision Tracking Built for Non-Linear Electronics Manufacturing

WISER’s asset locating system for electronics manufacturing tracks moving parts, tools, and assemblies in real time without relying on fixed workflows or manual scans. It maintains accuracy in metal-rich, signal-hostile environments where RFID and BLE systems fail.

This innovative functionality allows facility teams to gain reliable, real-time visibility without disrupting their existing production flow. This same resilience makes it ideal for semiconductor facilities, where wafers, carriers, and tools move through variable process steps across multiple cleanroom zones.

Designed for High-Mix, High-Value Workflows

Electronics lines run complex jobs with frequent changeovers, specialized tooling, and tight quality controls. WISER supports this by tracking every tagged asset individually, no matter how unpredictable the routing or staging. From PCB assemblies to semiconductor fabrication, WISER supports high-mix production where every asset’s location and process history matter.

The system adapts to dynamic floor layouts and non-linear workflows, capturing detailed movement history for each part or subassembly.

WIP Asset Locating for Electronics & Automotive Subassemblies

Electronics and automotive subassembly lines demand total visibility of in-progress materials, tools, and components – especially when workflows shift or bottlenecks appear without warning. Some of the most common applications include:

- PCB Assembly Zones: Track boards through soldering, inspection, and rework without manual scans

- Automotive Electronics Subassembly: Monitor harnesses, sensors, and modules across multiple lines

- Tool and Cart Tracking: Ensure location and readiness of shared tools, ESD-safe carts, and fixtures

- Quality and Calibration Areas: Maintain full visibility and automatic audit trails for assets under inspection, calibration, or quality hold

- WIP Staging and Buffer Zones: Locate partial builds and prevent slowdowns caused by misplaced work

- Semiconductor Fabrication and Packaging: Track wafers, carriers, and process tools across cleanroom zones for precise, contamination-safe visibility

By bringing real-time location data into these key processes, manufacturers reduce search time, tighten traceability, and avoid delays that compromise delivery schedules.

Where Our Asset Locating System Makes the Biggest Impact

WISER’s electronics WIP asset locating system provides critical tracking in areas where parts frequently stall or disappear.

It excels in non-linear environments with flexible workstations, mobile storage, and floating inspection zones.

Manufacturing teams use it to monitor key components across simultaneous builds. In PCBA and related electronics processes, it brings clarity to rework loops, test bays, and isolation areas.

These are zones where assets vanish and where WISER makes them visible.

Key Features of WISER’s RTLS for PCB Assembly and Subassembly Lines

WISER’s asset locating system for PCB assembly delivers the precision and reliability electronics manufacturers need to stay on schedule and in control. The system works flawlessly for real-world complexity, offering features that actually solve problems instead of just looking impressive on a spec sheet.

Below are some of the key features of our asset locating system for electronics manufacturing:

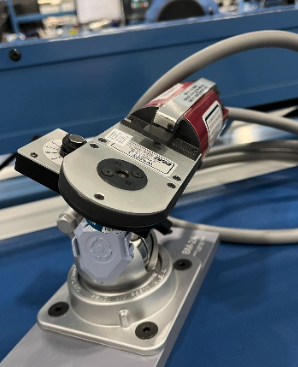

- Sub-meter accuracy using ultra-wideband signals for precise asset tracking in dense production zones

- Auto-calibrating mesh network that maintains performance in shifting layouts and metal-rich environments

- No manual scans or checkpoints, with continuous monitoring across non-linear workflows

- Rugged, industrial-grade tags designed for carts, totes, PCBs, tools, and high-mix WIP

- Customized Real-time dashboards and alerts to surface asset location, dwell time, and movement history

- Open API and system integrations for direct links to MES, ERP, or quality control systems

These features give electronics and automotive subassembly teams the visibility and control required to manage every part, every time, without slowing production. That’s the WISER guarantee.

See Why Electronics Manufacturers Trust WISER

Electronics and automotive subassembly teams use WISER’s asset locating system for real-time visibility, fewer delays, and complete control of their WIP. If you’re struggling to track assets through PCB assembly, semiconductor fabrication, rework stations, or high-mix production lines.

Schedule a demo or contact our team to find out how WISER can support your facility’s specific workflow.

Electronics WIP Asset Locating Systems FAQ

Learn more about WISER’s asset locating systems through our frequently asked questions below.

Can WISER’s asset locating system for electronics manufacturing track small items like PCB totes, bins, or trays?

Yes! Our system tracks small, high-volume containers, including PCB trays, totes, and bins with compact, low-profile tags for electronics environments.

How does the system handle multi-floor or complex facility layouts?

WISER’s asset locating system for electronics manufacturing uses a wireless mesh that scales across buildings, floors, and zones without losing accuracy or requiring fixed pathways.

What kind of maintenance do the tracking tags require?

Tags are maintenance-free for years. Battery life varies by update rate, but most electronics and WIP applications run for several years without replacement.

Can I integrate this with our existing ERP or MES?

Yes. WISER’s open API connects with ERP, MES, or quality systems to sync asset location with your existing production data.

Is the system suitable for ESD-sensitive environments?

Absolutely. Our electronics WIP asset locating system includes tag and mounting options that are compatible with ESD protocols and cleanroom use.

Is WISER’s system suitable for semiconductor cleanrooms?

Yes. WISER’s ultra-wideband system operates reliably in semiconductor environments with cleanroom-compliant, ESD-safe tags and minimal infrastructure impact.