Technology Comparison

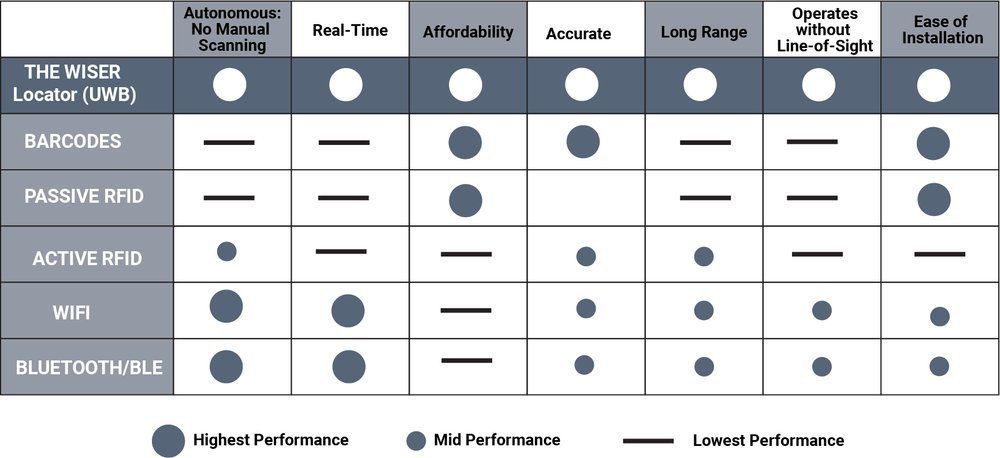

The WISER system reliably and affordably locates objects and people in real time. This innovative real-time location system (RTLS) does so accurately, granularly, and autonomously without expensive infrastructure and manual processes. End users can deploy WISER’s FCC-certified Locator system nearly anywhere, since it operates both indoors and outdoors across all types of environments.

See WISER’s guide to asset tracking technologies for a more general overview of these various technologies.

How does The WISER Locator work?

Patented Redundant Radio Localization and Tracking (RRLT) technology gives the WISER Locator a decided edge over conventional RTLS solutions. RRLT incorporates best-in-class ultra-wideband (UWB) technology as well as various proprietary measurement and data aggregation techniques, enabling consistent precision and reliability in factories, warehouses, healthcare facilities, aerospace hangars, and across many other settings and use cases.

Wireless UWB devices signal to one another to establish a tracking arena. Within the arena, WISER’s Tag and Track software calculates inch-level tag coordinates from these signals. Tag and Track then displays real-time location data on a site map or floor plan. Backend integration via WISER’s API can also send location data directly to an IoT dashboard, ERP, MES, or another software tool.

Advantages of WISER's RRLT

WISER

OTHERS

The WISER Locator gives end users hands-off, autonomous asset identification, tracking, and location. This eliminates the need for manual scanning.

RFID and barcodes use point-of-scan systems. This typically involves manual search-and-scan labor or expensive and cumbersome choke-points like doorway readers and static scanners.

WISER’s plug-and-play installation does not require manual measurements of device locations. The system calibrates wirelessly to save time and money for end users.

Laser-measurements are the norm for many RTLS installations. This slows system setup, adds costs for any adjustments, and often requires specialized equipment or training.

The WISER Locator delivers highly precise location even in cluttered, reflective environments like factories and warehouses.

Traditional RTLS solutions are inaccurate and unreliable around metal, reflective surfaces, and clutter, or in other harsh industrial environments.

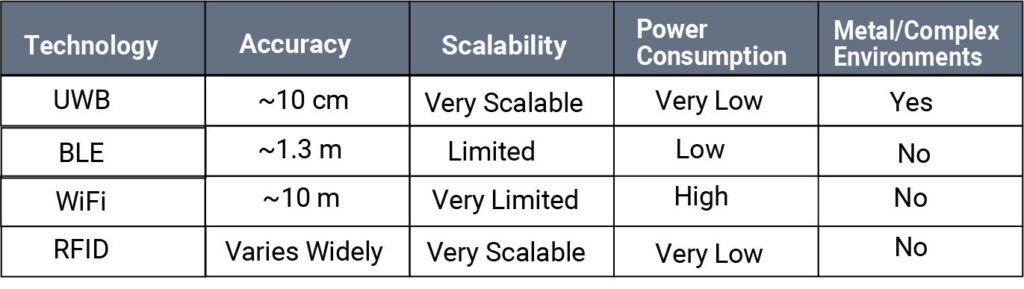

WISER RRLT enables sub-meter accuracy in nearly any setting, with inch-level precision in most cases.

BLE and WiFi RTLS typically give room-level accuracy but struggle to pinpoint location beyond a few meters.

Tag and Track delivers live, real-time, continuous location monitoring around the clock without manual effort.

Point-of-scan solutions like barcodes and RFID only show asset identification at a set time or place, making continuous location all but impossible.

The WISER Locator does not require or interfere with existing wireless networks like WiFi.

Many BLE, RFID, and even UWB RTLS solutions require WiFi for data back-haul, which adds significant costs and security concerns to RTLS installations.

The WISER Locator operates indoors, outdoors, and even underground.

Conventional RTLS solutions often operate only indoors or outdoors—not both.

WISER installations scale modularly with lightweight, portable devices. This allows tracking arenas to expand point by point without adding permanent infrastructure.

Most RTLS technologies require fixed reading portals, preset wiring, or other constant infrastructure. This adds expense and makes regular system adjustments or updates unfeasible.

WISER tags are fully reusable. WISER tag batteries last for years without replacement and send power-level updates in real time.

GPS, cellular, and many other location devices require constant battery replacements and recharging. Many RTLS tags are also not reusable when a battery fails.