To use ultra-wideband (UWB) for accurate tracking, tags need to be active devices, requiring a battery. At WISER, we’ve designed our tags so their replaceable batteries can last well over 5 years. A WISER rep can advise just how many years based on your specific use case. Aside from not ignoring low-battery notifications, customers do not need to give batteries any further thought. Still, I thought it would be interesting to dive into the technical details behind how we get years of battery life from such a tiny power source.

Deep Sleep

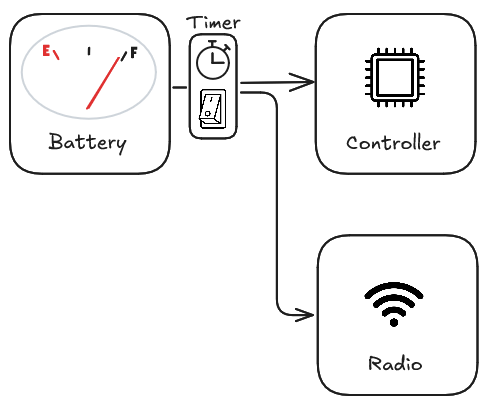

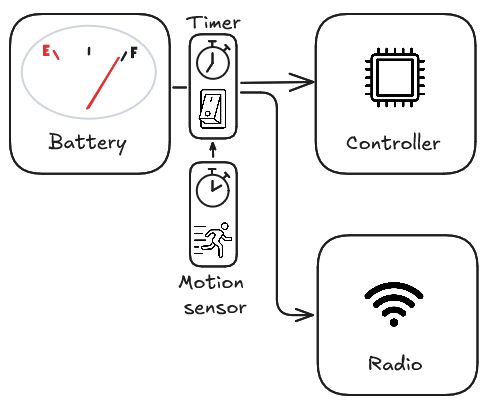

Most modern circuit components provide a low-power “sleep” state, an output-disable control, or can simply be powered off when not in use. This includes the most power-hungry devices on our tag, the microcontroller and the UWB transceiver radio. The radio, in particular, might draw over 0.1 amps when transmitting, but less than 0.000001 amps in sleep mode!

Extending battery life then involves two key goals: minimizing power consumption during sleep and maximizing the time spent in that sleep state. The circuit wakes up briefly, triggered by a timer, uses the smallest amount of energy possible to get its work done, then immediately returns to sleep.

For the wake period, it’s helpful to move away from thinking about continuous power draw (like you may be used to for a 60 W lamp plugged into the wall) and instead conceptualize the battery as an energy reservoir, from which the circuit takes discrete “gulps” of energy. Our aim is to reduce the number and duration of those gulps.

Are we moving?

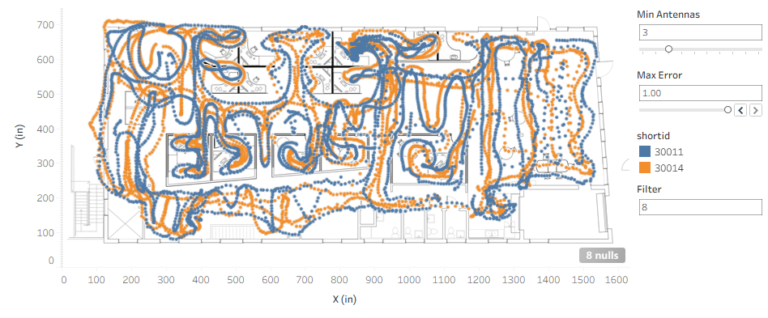

Tags operate by periodically sending out a radio “ping” to allow the system to determine their locations. Because each position measurement has some statistical uncertainty, multiple measurements are needed to reach the highest accuracy. But if we know a tag isn’t moving, maybe waiting on a shelf or hanging on a rack, we can reduce how often we sample its position. Fewer pings means longer battery life.

We determine if the tag is moving with an onboard motion sensor. We configure two different ping rates, a slower rate for when the tag is not moving and a second faster rate when it’s on the move. This is why it’s crucial to work with your WISER rep to understand your use case. A tag sitting in storage will use less battery power than a tag that needs to be located as accurately but that is also moving constantly across three shifts.

In the photo above is a motion switch used in some WISER tags that I’ve cracked open, next to a quarter and thumbtack for scale. In this age of semiconductors, I love how mechanical it is. When stationary, the ball bearings complete an electric circuit, but small movements will cause brief interruptions that trigger the controller to wake up. (The mechanism reminds me of an old-timey carbon microphone.)

The Big Picture

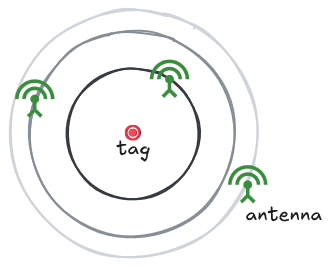

Our next big savings doesn’t come from the tag at all, but a system-level design choice. First, we’ll have to briefly review how we use UWB to measure distance to locate a tag.

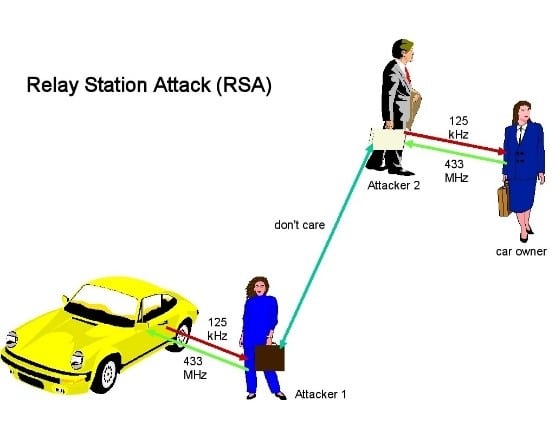

It is easy (relatively) to measure what time a radio transmission is received, and since the speed of radio waves is well known, we could measure the distance to the transmitter if we also knew what time the transmission was sent. The tricky part is that radio waves are very, very fast, so the clocks on the sender and receiver must be well synchronized. Traditionally, that requires sending and receiving signals back-and-forth in both directions to check the time difference before we can calculate the distance.

As a fun tangent, older keyless entry cars were susceptible to a “relay” attack. Burglars would use their own radios to re-broadcast the key’s signal, bridging the large distance between a car in the parking lot and its key inside a building. No amount of cryptographic key exchange would reveal the delay caused by the re-broadcast. Modern cars solve this by exchanging UWB signals between the key and the car as above to measure the physical distance in a way that can’t be faked.

However, using UWB to measure distances in this way consumes battery energy not just when transmitting but also when receiving signals, and several exchanges are required to triangulate a tag’s location. But the mobile tags and stationary antennas in WISER’s system have an important difference; the antennas are typically plugged into the wall or a large battery (such as solar powered) where energy is less of a concern.

The WISER system leverages proprietary algorithms to first synchronize clocks across any number of stationary antennas (even in complex environments). Even if a tag only broadcasts, and only broadcasts once, we can use the difference in time each antenna receives that broadcast to effectively calculate what time the transmission was sent and where it must be located. This method is called Time Difference of Arrival (TDOA). WISER does additionally leverage the bidirectional method described first in special cases. We call this “Hybrid” mode.

The takeaway here is, the tag never has to spend energy receiving messages. We are offloading (with no small amount of engineering difficulty) as much work as possible from the battery device to the devices running on wall power.

Standby power

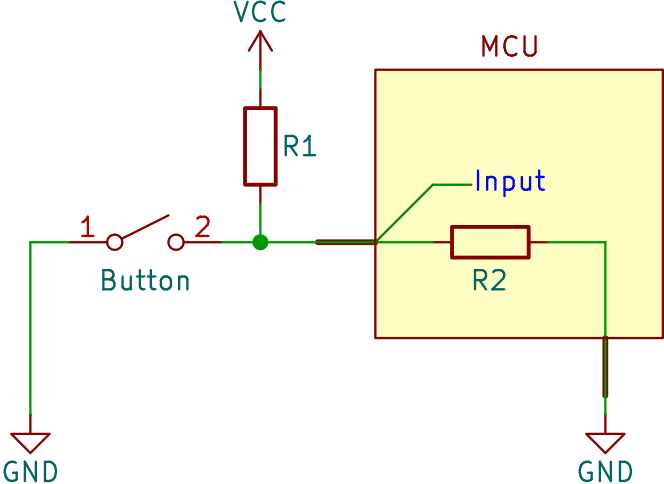

All of the considerations above are for naught if the standby power is not small enough. And now we finally need to talk Electrical Engineering. Like cutting many small holes in a dam, we need to be careful selecting our components for low quiescent current and designing our circuit for low leakage.

We need to select a battery chemistry with a small self-discharge, that is, how much energy it loses just sitting on a shelf unused. The LiPo battery in a smartphone can lose as much as 1% per day. The coin cells used in WISER tags lose less than 1% per year. We must select a controller with a small sleep current, and this can vary dramatically between microcontrollers and depending on which of several sleep state is used. DC regulators are often culprits of high quiescent current. Many capacitors, particularly those designed for AC applications, electrolytic, and tantalums may have high leakage.

A common pitfall are pull-up and pull-down resistors on a microcontrollers IO pins, data buses, and chip-selects. Every path we can draw from positive to ground is a potential leak. Pull-up and down’s internal to the microcontroller can easily go unaddressed or only become a problem when the controller is in a less-defined sleep state. Depending on the tolerable RC time constant, these can often be replaced with higher valued external resistors, or MOSFETs if not.

Calculation

Putting it all together, we can calculate the expected battery life for our tags as follows. The “energy per ping” and the “standby power” ultimately have to be measured empirically.

Testing and Calculation

But how do we verify a battery will last 5 years in practice? At WISER, we have been running and shipping tags to customers for well over that 5 years, so we get to cheat a little and look at real data. But how does an engineer confirm a new design?

In short, the performance can (usually) be reliably extrapolated. Most components operating within their environmental specifications (for things like temperature, shock, etc.) won’t degrade significantly over a period of years. We can check an unusual component with the manufacturer.

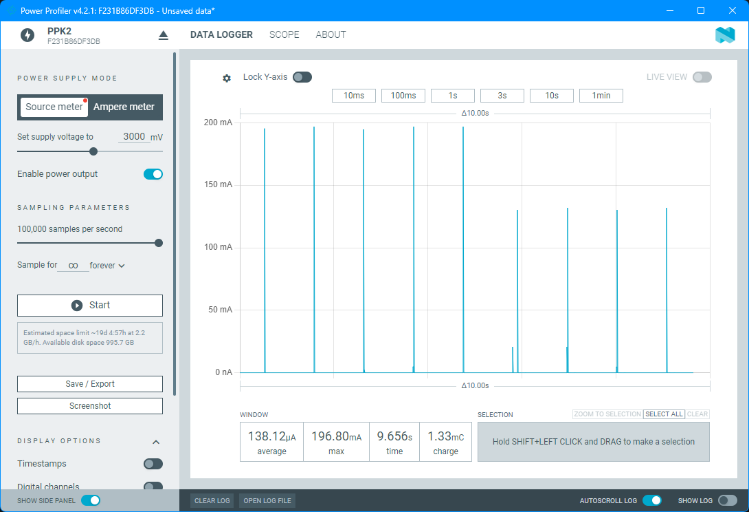

Next we need to measure the power usage over a short period of time. For price-to-performance, Nordic’s Power Profiler 2 (PPK2) is hard to beat. It can function either as a source meter or as an ammeter between the battery and circuit. The PPK2 can even be interacted with programmatically to make it easy to integrate into hardware-in-the-loop testing.

The screenshot above is a recording for a random development board I had lying around. You can see it broadcasting briefly once a second, and the low sleep current in between.

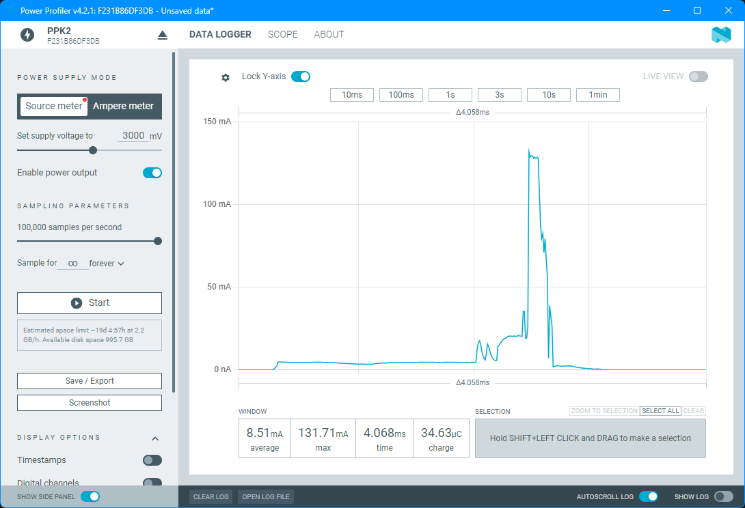

If we zoom in on one of those pulses, we see an initial low power period where only the microcontroller is awake, a short increase in power draw as the radio transmitter wakes up, and finally a large power burst when transmitting, before going back to sleep.

The PPK2 also has a (very basic) logic analyzer, allowing an output pin toggled in firmware to be synchronized with the current measurements, the equivalent of a hardware printf() statement. It may be useful to remove any large circuit capacitors when doing this.

In the meter’s UI, we measure the area under the curve, totaling the power used for the time window. We do this both for the active period, our “energy per ping,” and the rest period, our “standby power.” Because we are engineers, we add a healthy safety margin to these numbers to account for any differences between tags, variations due to temperature, and so on. Finally, we can plug these numbers into the equation above to calculate the expected lifetime.

Conclusion

In short, long battery life isn’t magic—it’s the careful sum of deep-sleep firmware, motion-aware sampling, clever system architecture, and obsessive component selection. By squeezing every microamp during standby, treating radio bursts as “energy sips,” and pushing the heavy math to wall-powered infrastructure, we turn a coin cell into half a decade of reliable tracking. So when a WISER tag quietly blinks to life after months on a warehouse shelf, remember that you’re seeing hundreds of tiny engineering decisions working in concert—proof that, with the right design philosophy, big performance can indeed live inside a very small battery.